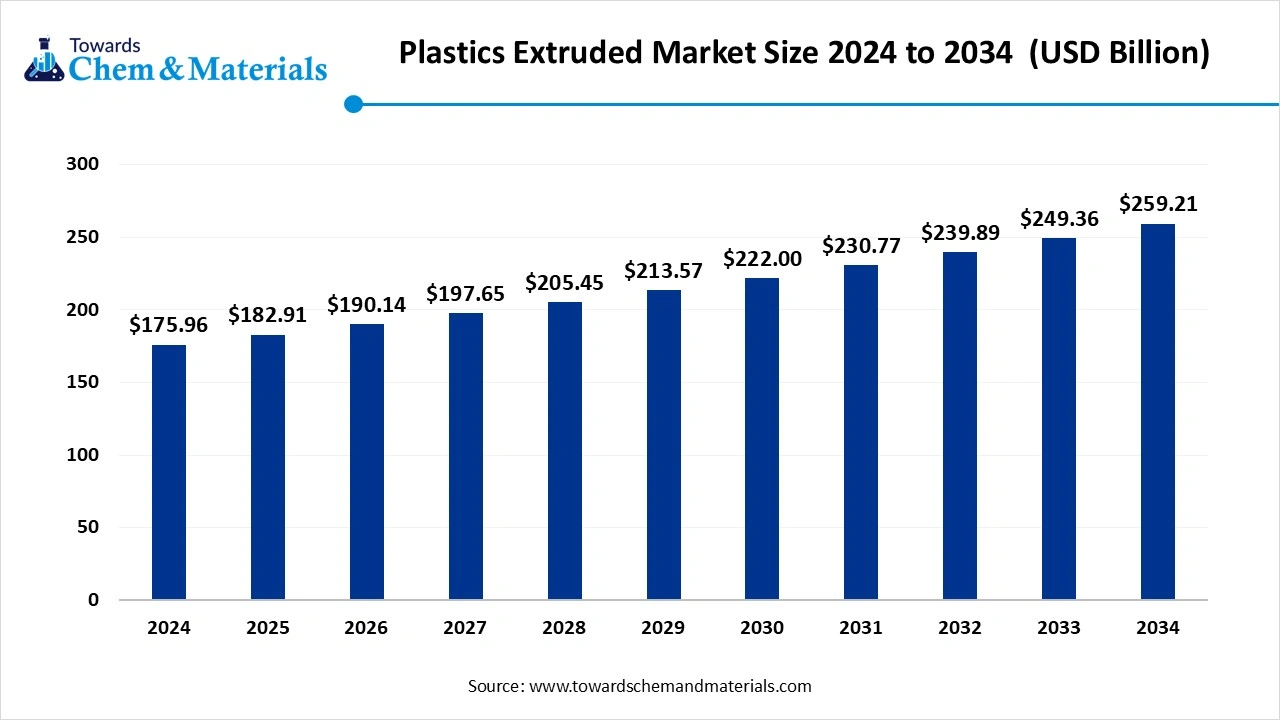

Plastics Extruded Market Size to Worth USD 259.21 Billion by 2034

According to Towards Chemical and Materials, the global plastics extruded market size is calculated at USD 182.91 billion in 2025 and is expected to be worth around USD 259.21 billion by 2034, growing at a compound annual growth rate (CAGR) of 3.95% over the forecast period 2025 to 2034.

Ottawa, Oct. 08, 2025 (GLOBE NEWSWIRE) -- The global plastics extruded market size was valued at USD 175.96 billion in 2024 and is anticipated to reach around USD 259.21 billion by 2034, growing at a compound annual growth rate (CAGR) of 3.95% over the forecast period from 2025 to 2034. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

The Rising demand for lightweight, durable and cost-effective materials in construction and automotive industries is driving growth in the plastic extruded market.

Download a Sample Report Here@ https://www.towardschemandmaterials.com/download-sample/5758

Plastics Extruded Overview

The plastics extrusion market is expanding as manufacturers increasingly favour lightweight, cost effective materials over heavier alternatives across many industries. Widely used processes force melted or softened plastics through dies to produce continuous cross sectional shapes such as films, sheets, profiles, pipes, and tubes. The market is driven by demand in packaging, automotive, and construction, among others, where plastics extrusion offers high throughput and material efficiency.

The Sustainability trends are influencing the market, with growing interest in recyclable and bio-based plastics, as well as multi-layer and barrier film technologies. Regionally, Asia Pacific is the key zone of activity owing to rapid industrialization and infrastructure and development, while regions with strong regulatory pressure for sustainable materials are pushing innovation. Challenges include volatility in raw material (petroleum derived) prices, which affect production cost and supply stability. Opportunities lie in customized extrusion solutions for niche sectors like medical, aerospace, and renewable energy, where precision and material properties are increasingly crucial.

Plastics Extruded Market Report Highlights

- The Asia Pacific plastics extruded market size was estimated at USD 70.38 billion in 2024 and is anticipated to reach USD 104.18 billion by 2034, growing at a CAGR of 4.00% from 2025 to 2034.

- By region, Asia Pacific dominated the plastics extruded market in 2024 with 40% of the industry share, akin to the enlarged expansion of sectors such as packaging, automotive, and construction.

- By material type, the polyethylene extrusion segment led the market in 2024 with 35% market share, owing to the increased need for high-quality plastic in the region nowadays.

- By process type, the single screw extrusion segment emerged as the top-performing segment in the market in 2024 with 40% industry share, due to it being considered the traditional process and its unique properties, such as the cost effectiveness and simplicity, in recent years.

- By product type, the pipes and tubes segment led the market in 2024 with 30% market share, due to the sudden updating of the regional infrastructure globally.

- By end-use industry, the packaging segment led the market in 2024 with 25% industry share, due to its widespread use in consumer goods, food & beverages, and industrial applications.

- By equipment type, the extruders segment led the market in 2024 with 50% industry share, as they form the core of the plastic extrusion process.

- By application type, the packaging films segment led the plastic extrusion market in 2024 with 35% industry share, due to their extensive use in food, personal care, pharmaceuticals, and industrial packaging.

Buy Now this Premium Research Report at a Special Price Against the List Price With [Express Delivery] @ https://www.towardschemandmaterials.com/price/5758

Plastics Extruded Market Report Scope

| Report Attribute | Details |

| Market size value in 2026 | USD 190.14 billion |

| Revenue forecast in 2034 | USD 259.21 billion |

| Growth rate | CAGR of 3.95% from 2025 to 2034 |

| Base year | 2024 |

| Historical data | 2021 - 2024 |

| Forecast period | 2025 - 2034 |

| Quantitative Units | Volume in kilotons, revenue in USD million/billion, and CAGR from 2025 to 2034 |

| Report coverage | Volume forecast, revenue forecast, competitive landscape, growth factors, and trends |

| Segments covered | By Material Type, By Process Type, By Product Type, By End-Use Industry, By Equipment Type, By Application, By Region |

| Regional scope | North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

| Country scope | U.S.; Canada; Mexico; Germany; France; UK; Italy; China; India; Japan; Australia; Brazil; Saudi Arabia |

| Key companies profiled | BASF SE, SABIC , DSM Engineering Plastics , Dupont , Saint-Gobain , Makrolon® , Michelman, Inc. , Leistritz Extrusionstechnik GmbH , Nordson Corporation, Prism Plastics Inc. , Jain Irrigation Systems Ltd. , PolyOne Corporation , Aluplast GmbH , U.S. Plastic Corp. , Zeus Industrial Products , WITTMANN BATTENFELD , Graham Engineering Corporation , Coperion GmbH , The Dow Chemical Company , Reifenhäuser GmbH |

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

What are the Benefits of using Plastic Extrusions over other Materials?

There are several reasons why plastic extrusion offers a more efficient and cost-effective method for producing plastic products. Plastic extrusions offer several benefits over other materials, including:

- Versatility: Plastic extrusions can be produced in a wide range of shapes and sizes, allowing for a high degree of customization to meet specific project requirements. They can also be made in a variety of colors and finishes, providing an aesthetic appeal.

- Cost-effective: Plastic extrusions are generally less expensive than other materials, such as metal or wood. They require less processing and labor, resulting in lower production costs.

- Lightweight: Plastic extrusions are typically lightweight, making them easy to handle, transport, and install. This can save on transportation costs and installation time.

- Durable: Plastic extrusions are resistant to corrosion, moisture, and chemicals, making them ideal for use in harsh environments. They are also less susceptible to damage from impact, reducing the need for frequent repairs or replacements.

- Energy-efficient: Plastic extrusions have good insulating properties, making them effective for use in energy-efficient building designs. They can also be made with recycled materials, reducing their environmental impact.

- Easy to fabricate: Plastic extrusions are easy to cut, drill, and shape, allowing for efficient fabrication and installation. They can also be joined together using a variety of methods, including welding, adhesive bonding, and mechanical fasteners.

What are the Different Types of Plastic Extrusion?

Depending on the die shape, different products can be formed using various available extrusion processes listed below:

1. Tubing Extrusion

This extrusion type is used for the extrusion of tubes and pipes. In this process, air with positive internal pressure may also be applied. The tubes or pipes after exiting the die are pulled into a cooling tank were they are normally water-cooled.

2. Blow Film Extrusion

This type is used for the production of plastic films tubes through a continuous sheeting. In this process the film tube melt is cooled before leaving the die, producing a semi-solid tube and blown to expand to a desired size and film thickness. This process is used for manufacturing of products such as shopping bags.

3. Sheet Film Extrusion

This type is used for the extrusion of plastic sheets or films that are too thick to be blown. After exiting the die, the sheets are pulled and cooled through a series of cooling rolls, which also regulate the sheet thickness.

4. Over Jacket Extrusion

This extrusion type is used for wire coating. In this process the wire is pulled through the centre of the die. If adhesion is required between the wire and the coating, pressure tooling is used. In this method the wire is covered in molten plastic whilst in the die and is pressurized when exiting the die. If adhesion is not required, jacketing tooling is used. In this method, the wire is covered by the melt as it exits the die.

Here Are Some Of The Top Products In The Plastics Extruded Market

- Extruded Sheets- Used in packaging, construction, signage, and automotive panels (e.g., polycarbonate, ABS).

- Pipes & Tubes- Widely used in construction, plumbing, irrigation, and medical sectors (e.g., PVC, HDPE).

- Films (Blown/Cast)- Essential for flexible packaging, agricultural films, and medical packaging.

- Window & Door Profiles- Primarily extruded from PVC for building and construction applications.

- Wires & Cable Insulation- Extruded thermoplastics like PVC and PE for insulation and jacketing.

- Weatherstripping & Seals- Used in automotive and construction industries for sealing and insulation.

- Plastic Rods & Bars- Used in machining, prototyping, and structural components.

- Plastic Coated Wires/Profiles- Wire coating or profile wrapping for various consumer and industrial applications.

- Medical Tubing- Precision extruded tubing for catheters, IV lines, etc., using TPU, PVC, PE.

- Plastic Siding & Cladding- Used in residential and commercial exteriors for protection and aesthetics.

What Are The Major Trends In The Plastics Extruded Market?

- The push toward biodegradable and recyclable plastics is growing, as sustainability becomes a priority for manufacturers.

- Increase in infrastructure and construction projects is boosting demand for extruded profiles like pipes, window frames, and cable duct.

- Films and sheets, agricultural, and electronics.

- Manufacturers are leveraging advanced tooling and precision die heads to provide customization, better quality, and more complex extruded shapes.

- Lightweight plastics are increasingly used in automotive and packaging to replace heavier materials, helping with fuel efficiency, emissions, and cost savings.

How Does AI Influence The Growth Of The Plastics Extruded Market In 2025?

AI is helping manufacturers in the plastics extrusion space to optimise their processes by analysing data from many sensors in real time, allowing adjustments to temperature, pressure, screw speed and melt flow so that output quality improves and waste drops. AI-driven predictive maintenance systems foresee equipment wear or impending failures before they cause stoppages, boosting uptime and lowering operational disruptions.

AI applications are enabling more consistent quality control via computer vision and machine learning to detect defects quickly, ensuring extruded products meet specifications with reduced scrap. In addition, AI supports sustainability by helping optimise blend formulations (such as mixing recycled with virgin material or bio based resins) and reducing energy consumption through tighter control of thermal or flow conditions. Finally, AI is enabling better demand and process forecasting, by analysing historical and real time data, firms can better match production to demand, plan maintenance, and reduce overproduction or inventory waste, contribution to more efficient capacity utilization.

Plastics Extruded Market Growth Factors

Could Rising Sustainability Demands Push Manufacturers Toward Greener Feedstock’s?

As consumers, governments, and industries increasingly demand reduced environmental impact, producers of extruded plastics are turning to recycled plastics, bio-based polymers, and cleaner processing methods. These shifts help manufacturers align with regulations, improve public image, and reduce reliance on fossil fuel derived raw materials, creating strong incentive for growth.

Might Energy Efficiency Innovations Make Extrusion More Competitive?

With energy costs rising and carbon regulations tightening, firms producing extrusion machinery are integrating new technologies such as energy regeneration, heat recovery, and optimized control systems. These innovations reduce operating expenses and environmental footprint, which boosts demand from manufacturers seeking lower cost and more sustainable operations.

Market Opportunity

Can Plastics Extrusion Power The AI Infrastructure Boom?

There is growing demand for high performance extruded plastics in data centres and AI infrastructure, because extruded profiles and cable management systems are crucial for insulating and protecting wiring, conduits, and sensitive electronics under high thermal and electrical loads. Manufacturers that can deliver engineering grade materials that withstand heat, fore and rigorous safety standards have the chance to serve a fast expanding segment tied to AI deployment and cloud computing.

Could AI Designed Recyclable Polymers Transform Waste Into Value?

Emerging work in AI informed polymer design aims to produce materials that are architecturally diverse but deconstruct able and recyclable without needing costly separation for mixed waste streams. If plastics extruders adapt to use these AI designed recyclable plastics, there is opportunity to capture demand from sustainability focused clients, reduce waste and compliance risk, and innovate in new product forms.

Limitations In The Plastics Extruded Market

- Raw Material cost and volatility: Price fluctuations of petroleum derived polymers such as polyethylene and polypropylene create unpredictability for manufacturers, raising production costs and sometimes delaying operations.

- Environmental regulations and sustainability pressures: stricter rules around plastic waste, recycling, and ecological impact are imposing compliance burdens, which may restrict market expansion or increase costs for extrusion producers.

Plastics Extruded Market Segmentation

Material Type Insights

Why Is Polyethylene Extrusion Segment Dominating The Plastics Extruded Market?

The polyethylene extrusion segment dominated the market in 2024, Polyethylene’s excellent chemical resistance, low moisture absorption, and ease of processing make it ideal for producing a wide range of extruded products, including films sheet, and pipes, the materials adaptability to various applications, coupled with its widespread availability, has cemented it dominance in the market.

The polypropylene extrusion segment is projected to experience the highest growth rate in the market between 2025 and 2034. The material’s superior fatigue resistance and chemical stability. These properties make polypropylene ideal for applications in automotive components, medical devices, and high performance packaging. The increasing demand for lightweight and durable materials, coupled with polypropylene’s recyclability, positions it as a key player in the evolving plastics extruded market.

Process Type Insights

Why Is Single-Screw Extrusion Segment Dominate The Plastics Extruded Market?

The single screw extrusion segment captured the largest share in the market in 2024. Single-screw extrusion remains the dominant process type, favoured for its simplicity and cost-effectiveness. This method is widely used in the production of pipes, films, and profiles, offering high throughput and ease of operation. The single-screw extruder’s ability to handle a variety of materials and its straightforward maintenance requirements contribute to its widespread adoption in the plastics extruded market.

The twin screw extrusion segment will gain a significant share of the market over the studied period of 2025 to 2034. Twin-screw extrusion is gaining momentum due to its enhanced mixing capabilities and versatility in processing a wide range of materials, including filled and recycled plastics. The intermeshing screws provide better homogenization, allowing for the production of complex profiles and compounds. As industries demand more customized and high performance materials, twin –screw extrusion is poised to capture a larger share of the market.

Product Type Insights

Why Are Pipes And Tubes Segment Dominated the Plastics Extruded Market?

The pipes and tubes segment dominated the market in 2024. The pipes and tubes segment leads the product type category, driven by the global expansion of infrastructure projects and the need for efficient waste and sewage systems. Extruded plastic pipes offer advantages such as corrosion resistance, lightweight handling, and ease of installation, making them a referred choice in construction and utility applications. The durability and cost effectiveness of plastic pipes further solidify their dominance in the market.

The films and sheets segment is expected to grow at the fastest rate in the market during the forecast period between 2025 to 2034. Films and sheets are experiencing rapid growth, fuelled by the increasing demand for flexible packaging solutions in the food beverage industry. The versatility of extruded films allows for applications ranging from protective packaging to agricultural films. Advancements in barrier technologies and the push for sustainable materials are further driving the adoption of extruded films and sheets.

End Use Industry Insights

Why Is Packaging Segment Dominating The Plastics Extruded Market?

The packaging segment captured a largest share of the market in 2024, owing to the widespread application of extruded plastics in packaging materials. Extruded films and sheets are extensively used for packaging consumer goods, food products, and pharmaceuticals, offering benefits like moisture resistance and printability. He growth of e-commerce and the need for efficient packaging solutions continue to drive the demand for extruded plastics in the packaging sector.

The automotive segment is projected to experience the highest growth rate in the market between 2025 and 2034. The automotive industry is rapidly adopting extruded plastics to reduce vehicle weight and improve fuel efficient. Extruded plastic components, such as trims, seals, and panels, offer advantages like corrosion resistance and design flexibility are further accelerating the use of extruded plastics in automotive applications.

Equipment Type Insights

Why Are Extruded Segment Dominating The Plastics Extruded Market?

The extruders segment captured a largest share of the market in 2024. Extruders are the cornerstone of the plastic extrusion process, responsible for melting and shaping plastic materials into desired profiles. Their carnality and ability to handle various materials make them indispensable in the production of extruded products. The continuous advancements in extruder technology, focusing on efficiency and precision, contribute to their dominance in the equipment type segment.

The die heads segment is anticipated to grow with the highest CAGR in the market during the studied years, due to the increasing demand for customized and high quality extruded products. They play a crucial role in determining the final shape and dimensions of extruder materials, making them essential for producing complex profiles, innovations in die head design, such as multi-layer co-extrusion and adjustable dies, and driving their adoption across various industries.

Application Type Insights:

Why Are Packaging Films Segment Dominating The Plastics Extruded Market?

The packaging films segment retained dominance in the plastics extruded market in 2024. Extruded plastic films offer advantages like lightweight, barrier properties, and ease of customization, making them ideal for packaging applications. The growth of online retail and the demand for sustainable packaging solutions continue to bolster the prominence of packaging films in the market.

The construction profiles segment is predicted to witness significant growth in the market over the forecast period of 2025 to 2034. Construction profiles are experiencing rapid growth, fuelled by the global boom in infrastructure development the housing projects. Extruded plastic profiles, such as window frames, door panels, and cable ducts, offer benefits like durability, weather resistance, and low maintenance. The shift towards sustainable building materials and the need for cost effective solutions are further driving the demand for extruded construction profiles.

Regional Insights:

What Makes Asia Pacific the Dominant Region?

Asia Pacific dominated the Plastics extruded market in 2024, because its rapid industrialization, booming infrastructure development, and rising demand from sectors like packaging, automotive, and construction are driving huge needs for extruded products such as pipes, films and profiles. Countries in the region are scaling up products such as pipes, films, and profiles, countries in the region are scaling up production capacity due to favourable manufacturing conditions, expanding domestic consumption, and export opportunities. The concentration of heavy manufacturing and investments in plastic processing technologies also reinforce its strong position.

China is particularly dominant thanks to its extensive manufacturing base, advanced extrusion machinery, large domestic consumption, and strong export orientation in plastics products. The country is heavily investing in technology and innovation to produce cost-effective extruded plastics, meeting both local demand and global orders. These factors enable China to both shape market trends a fulfil large scale infrastructure, packaging and industrial applications.

What Is North America The Fastest Growing Region In The Plastics Extruded Market?

North America is expected to expand rapidly in the market in the coming years, driven by factors such as increased demand for lightweight and durable materials across various industries, including construction , automotive, and consumer goods. This surge is largely due to the ongoing push for sustainability and energy efficiency in manufacturing processes, leading companies to adopt extruded plastics as a solution to reduce weight and improve performance. Additionally, advancements in extrusion technology and the expansion of infrastructure projects further contribute to the market’s growth in the region.

The United States stands out within North America due to its substantial market share and robust industrial base. In 2023, the U.S. accounted for a significant portion of the region’s plastics extruded market, benefiting from a diverse manufacturing sector and a strong emphasis on innovation. Key industries such as automotive, construction, and packaging heavily rely on extruded plastics for components like pipes, profiles, profiles, and films. The country’s focus sustainability, coupled with advancement in extrusion technologies, positions the U.S. as a leader in the market.

More Insights in Towards Chemical and Materials:

- Plastics Market : The global plastics market size was reached at USD 651.55 billion in 2024 and is expected to be worth around USD 984.11 billion by 2034, growing at a compound annual growth rate (CAGR) of 4.21% over the forecast period 2025 to 2034.

- Bioplastics Market : The global bioplastics market volume was reached at 11,40,000.0 tons in 2024 and is expected to be worth around 73,21,706.6 tons by 2034, growing at a compound annual growth rate (CAGR) of 20.44% over the forecast period 2025 to 2034.

- Mechanical Recycling of Plastics Market : The global mechanical recycling of plastics market size was reached at USD 37.85 billion in 2024 and is expected to be worth around USD 92.86 billion by 2034, growing at a compound annual growth rate (CAGR) of 9.39% over the forecast period 2025 to 2034.

- Commodity Plastics Market : The global commodity plastics-market size was valued at USD 498.55 billion in 2024, grew to USD 513.26 billion in 2025, and is expected to hit around USD 666.76 billion by 2034, growing at a compound annual growth rate (CAGR) of 2.95% over the forecast period from 2025 to 2034.

- Biodegradable Plastics Market : The global biodegradable plastics market size was reached at USD 13.19 billion in 2024 and is expected to be worth around USD 91.26 billion by 2034, growing at a compound annual growth rate (CAGR) of 21.34% over the forecast period 2025 to 2034.

- Recycled Thermoplastics Market : The global recycled thermoplastics market size was estimated at USD 57.85 billion in 2024 and is expected to hit around USD 145.34 billion by 2034, growing at a compound annual growth rate (CAGR) of 9.65% over the forecast period from 2025 to 2034.

- Circular Plastics Market : The global circular plastics market size was reached at USD 73.19 billion in 2024 and is expected to be worth around USD 182.21 billion by 2034, growing at a compound annual growth rate (CAGR) of 9.55% over the forecast period 2025 to 2034.

- Sustainable Plastics Market : The global sustainable plastics market size was valued at USD 410.73 billion in 2024, grew to USD 465.89 billion in 2025, and is expected to hit around USD 1,448.23 billion by 2034, growing at a compound annual growth rate (CAGR) of 13.43% over the forecast period from 2025 to 2034.

- Recycled Plastics Market : The global recycled plastics market size was reached at USD 83.19 billion in 2024 and is expected to be worth around USD 183.80 billion by 2034, growing at a compound annual growth rate (CAGR) of 8.25% over the forecast period 2025 to 2034.

- High Performance Plastics Market : The global high performance plastics market size was valued at USD 26.85 billion in 2024 and is estimated to reach around USD 65.57 billion by 2034, exhibiting a compound annual growth rate (CAGR) of 9.34% during the forecast period 2025 to 2034.

- U.S. Plastics Market : The U.S. plastics market size was reached at USD 92.66 billion in 2024 and is expected to be worth around USD 131.34 billion by 2034, growing at a compound annual growth rate (CAGR) of 3.55% over the forecast period 2025 to 2034.

- U.S. Biodegradable Plastics Market : The U.S. biodegradable plastics market size is calculated at USD 2.14 billion in 2024, grew to USD 2.34 billion in 2025, and is projected to reach around USD 5.27 billion by 2034. The market is expanding at a CAGR of 9.44% between 2025 and 2034.

- U.S. Recycled Plastics Market : The U.S. recycled plastics market size was reached at USD 52.85 billion in 2024 and is expected to be worth around USD 131.33 billion by 2034, growing at a compound annual growth rate (CAGR) of 9.53% over the forecast period 2025 to 2034.

- Europe Bioplastics Market : The Europe bioplastics market volume was reached at 7.45 million tons in 2024 and is expected to be worth around 40.16 million tons by 2034, growing at a compound annual growth rate (CAGR) of 18.35% over the forecast period 2025 to 2034.

- Asia Pacific Bioplastics Market : The Asia Pacific bioplastics market volume was reached at 2.51 million tons in 2024 and is expected to be worth around 11.13 million tons by 2034, growing at a compound annual growth rate (CAGR) of 16.07% over the forecast period 2025 to 2034.

- Europe Plastics Market : The Europe plastics market volume was reached at 55.10 million tons in 2024 and is expected to be worth around 64.32 million tons by 2034, growing at a compound annual growth rate (CAGR) of 1.56% over the forecast period 2025 to 2034.

Plastics Extruded Market Top Key Companies:

- BASF SE

- SABIC

- DSM Engineering Plastics

- Dupont

- Saint-Gobain

- Makrolon®

- Michelman, Inc.

- Leistritz Extrusionstechnik GmbH

- Nordson Corporation

- Prism Plastics Inc.

- Jain Irrigation Systems Ltd.

- PolyOne Corporation

- Aluplast GmbH

- U.S. Plastic Corp.

- Zeus Industrial Products

- WITTMANN BATTENFELD

- Graham Engineering Corporation

- Coperion GmbH

- The Dow Chemical Company

- Reifenhäuser GmbH

Recent Developments

- In July 2025, In a strategic move to enhance its technical expertise and product offerings, star Plastics has merged with Trivalence Technologies. This merger aims to expand the companies’ capabilities and geographic each, thereby strengthening their position in the plastics extrusion market.

- In August 2025, the plastic Extrusion World Expo is scheduled to take place in November 12-13,2025, at the Huntington Convention Centre in Cleveland, Ohio. This event is set to be North America’s largest plastics industry gathering of the year, featuring over 300 exhibitors and offering numerous networking opportunities for professionals in the field.

Plastics Extruded Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2034. For this study, Towards Chemical and Materials has segmented the global Plastics Extruded Market

By Material Type

- Polyethylene (PE) Extrusion

- Polyvinyl Chloride (PVC) Extrusion

- Polypropylene (PP) Extrusion

- Polystyrene (PS) Extrusion

- Acrylonitrile Butadiene Styrene (ABS) Extrusion

- Polycarbonate (PC) Extrusion

- Others (Polyamides, PET, etc.)

By Process Type

- Single-Screw Extrusion

- Twin-Screw Extrusion

- Ram Extrusion

- Micro-Extrusion

- Co-extrusion

- Blown Film Extrusion

- Injection Extrusion

By Product Type

- Films & Sheets

- Pipes & Tubes

- Profiles & Molding

- Compounds & Granules

- Wires & Cables

- Others (Fittings, Geomembranes)

By End-Use Industry

- Construction

- Packaging

- Automotive

- Electronics

- Medical & Healthcare

- Consumer Goods

- Agriculture

- Others (Textiles, Aerospace)

By Equipment Type

- Extruders

- Die Heads

- Cooling Systems

- Cutters

- Others (Mixers, Conveyors)

By Application

- Packaging Films

- Construction Profiles

- Automotive Parts

- Medical Tubing

- Agricultural Films

- Electrical Insulation

- Others (Flooring, Furniture)

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/price/5758

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | Towards Consumer Goods | Nova One Advisor |

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.